The Goodyear Innovation Centre and the University of Luxembourg teamed up in a CORE-funded Public-Private-Partnership (PPP) project aiming to create and analyse surface-induced interphases in a macroscale planar material assembly.

So-called interphases are tiny, often property-changed domains that emerge at the interface between two different materials. Although they naturally rarely exceed the nanometre scale, they are extremely influential on the final properties of a composite material: at best significantly improving certain properties or even producing completely new ones.

Creating novel surface-induced interphases

In a first step, SIMOP aims to elucidate the role of interphases in the chemical, physical and/or technological properties of composite materials already used by Goodyear. The researchers’ chief aim, however, is to create novel, surface-induced interphases by applying epoxies and elastomers to structure-stimulating surfaces. Potentially, this technique could even result in entirely new materials.

Dr Georges Thielen from the Goodyear Innovation Centre provides an example of the interphases’ power: simply adding micro-sized silica fillers to a tyre’s rubber mix alters polymer chain mobility. Such systems as a whole can withstand higher forces before they are deformed.

These changes seem to stem from an area of polymers in close proximity to the silica filler, namely the interphase.

However, inner interphases of a tyre composite material are minute and hardly accessible, making a detailed study virtually impossible. Unless, of course, you have access to a clever modelling system – such as the one already used by Dr. Roland Sanctuary and colleagues from the University of Luxembourg – and manage to adjust it to fit your purposes.

Thus, a promising Public-Private-Partnership is born. Sanctuary and the team from the Laboratory for the Physics of Advanced Materials (LPM) are experts on the use of planar substrate surfaces for epoxy interphase analysis.

Simulating and studying interphases on a macroscopic level

SIMOP’s objective is to use the same method for the analysis of elastomer interphases as they appear in tyres: the planar substrate surface will enable the researchers to simulate and study interphases in tyre composite materials on a macroscopic level. This should help them gain a better understanding of interphase emergence, growth, structure and properties, with the hope that new insights gained through the simulation model can later be applied to the multi-component system of the tyre as a whole.

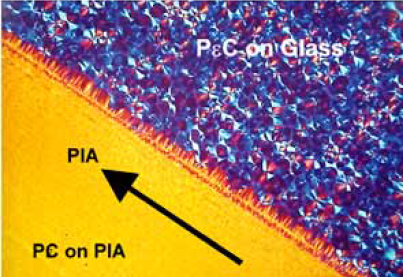

The ultimate aim, however, is to create new and optimised interphases and potentially entirely novel materials by using structure-stimulating substrates such as nano-structured polytetrafluoroethylene (better known as PTFE or Teflon), surface-treated thermoplastics or porous glasses. PIA (PTFE Induced Alignment) films have a monocrystalline, that is to say a regular, surface structure. Reactive polymers such as epoxies, one of the LPMs areas of expertise, or phenol formaldehyde resin, used for the reinforcement of rubber in tyres, will both be applied to the films and should provide some interesting results.

A novel approach: Using porous glasses to create interphases

It is perhaps unexpected to see that the University’s work on epoxies, which has no immediate relevance to Goodyear, continues within the scope of this particular project, but Thielen fully endorses this. After all, Goodyear’s PPPs run under an Open Innovation programme.

“The ultra-thin highly oriented PIA films are able to organise and orient different types of linear molecules due to their monocrystalline surface structure. We expect textured interphases to appear between the Teflon substrate and the reactive polymers,” Sanctuary explains. A few years ago, members of the lab used the technique to develop new materials with a tremendous improvement of properties such as ferroelectricity.

The use of porous glasses for the creation of interphases has not been tried yet, but also seems highly promising. “Different alignments of the elastomer molecules would produce different properties,” explains Dr Carolin Welter, staff engineer at Goodyear. “It would be interesting to see whether such properties could be transferred directly to a tyre.” One of the company’s priority targets is to enhance the tyres’ properties in a high frequency setting, as is the case under ABS braking conditions.

The University does not only innovate in the creation of their interphases, but also in their analysis strategy. The researchers use two main methods:

Differential Scanning Calorimetry and Brillouin spectroscopy – however with a twist. According to Sanctuary, their application of the Brillouin spectrometer as a Brillouin microscope, a recently developed technique and now used for the investigation of the interphases in the focus of SIMOP, is a unique approach only made at the LPM.

Partnerships with research “extremely desirable” for companies

Public-Private-Partnerships like the one in SIMOP are extremely desirable to companies such as Goodyear, Thielen explains: “The externalisation of research is a fundamental strategy of the Goodyear Open Innovation programme: since 2008, we have started building up various partnerships with public institutions. A company like Goodyear simply cannot afford to build up the level of expertise required for such innovative research.”

Open innovation and Public-Private-Partnerships allow for dialogue and the sharing of expertise, know-how and equipment in order to achieve interesting results for both sides. As Sanctuary adds:

“PPPs can be an efficient instrument that allows the scientists at the University to define new and highly topical fields for fundamental research. Deepening the understanding of physical processes in technically relevant materials can help the industrial partner to substantially improve their product.”

PPPs increase competitiveness and push research – often further than a private company alone could ever do. Sanctuary explains: “As far as the challenging run for innovative materials is concerned, public research generally has greater staying power than the private partner to try many and even risky pathways leading to the development of new ideas with an important potential for industry.“

This case study was originally featured in the 2010 FNR Annual Report (PDF)

SEE ALSO

RELATED PAGES

RELATED PROGRAMMES